How We Accidentally Became Tugger Train Efficiency Experts - Origin Story

During the vibrant Web Summit in 2019, we were showcasing Azitek's asset-tracking technology when an Innovation Director from a leading automotive supplier approached us with a simple question that would pivot our journey. He asked if we could track tugger trains in their facility. Honestly, the term 'tugger train' was new to us, let alone grasping the criticality of the milk-run concept in manufacturing intralogistics. But, in true startup spirit, we accepted the challenge, confident in our versatile technology developed from the ground up – from the hardware to the cloud.

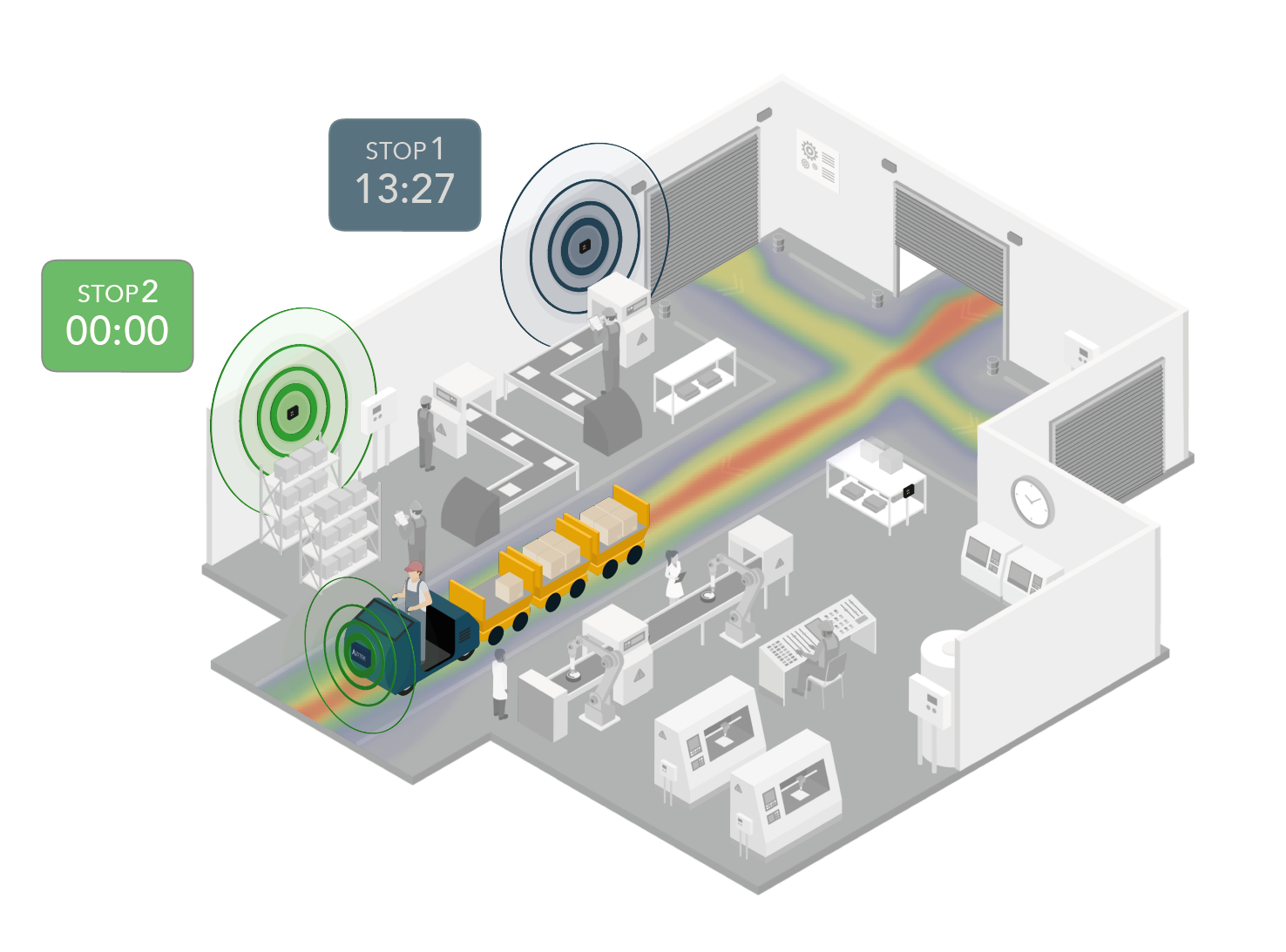

We aimed for a proof of concept that was simple and swift to implement, cutting through the red tape of authorizations and bureaucracies. Our strategy? To locate tugger trains at various checkpoints across the shop floor using battery-powered beacons as reference points. Remember, this was for an innovation department. It would be many steps before this customer would want to buy production-grade solutions. This quick approach ensured an effortless setup, free from the constraints of prior installation requirements. To integrate seamlessly into the vehicles, we customized the Gateways to connect to the vehicle's battery with a tailor-made cable.

Fast forward a few months, and we found ourselves tracking a tugger train across the facility, covering up both warehouse and production areas, with 20 reference points. Our solution was fully offline at this time, simply recording position logs and storing them in internal memory. However, the real test began when we faced the harsh realities of intralogistics – power connection instabilities and a difficult environment that tested the durability of all our hardware. But, after a month of trial and some setbacks, we successfully extracted the tracking data for analysis.

During this deep dive into the data, the real challenge revealed itself: Providing meaningful insights and metrics for the tugger train routes was a lot more difficult than we initially thought. Given the dynamic and, sometimes, erratic paths these vehicles took. Route discrepancies proved to be one of the first key metrics. Once we solved that, we moved on to other KPIs.

As is so common with innovation projects, despite delivering a detailed report from our one-month proof of concept, our first potential client chose not to proceed. However, the problem, now clearly understood, was still present. This realization inspired us to investigate further and validate if other tugger train users were facing the same lack of data. Once confirmed, we decided to double down, evolving our solution into an online platform that monitors tugger trains 24/7, offering real-time metrics and custom analytics tailored to each vehicle, route, and work shift.

Two years later and after several implementations, our persistence paid off. Armed with a robust and comprehensive solution, we revisited our initial prospect and successfully closed the deal. This original multinational, with nearly a hundred facilities, not only embraced our technology for all of their tugger trains but also became the catalyst for our expansion into more of their locations.

Right now, we're proud to offer what we believe is the only comprehensive package for monitoring tugger trains in the market. Going forward, we're committed to continue solving this challenge and enhancing our unique solution.

José Valente, CEO & Co-Founder

Jan 2024